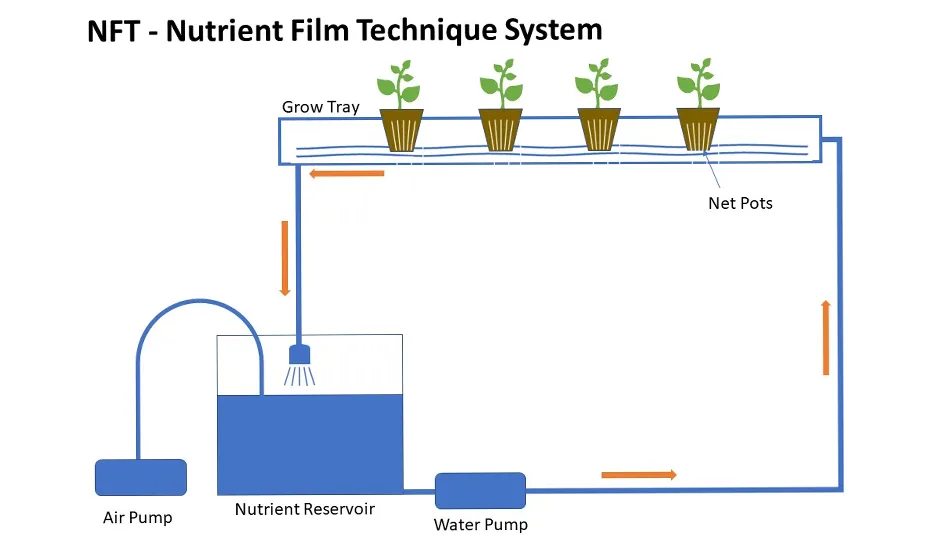

The core of the NFT (Nutrient Film Technique) system is a "thin, continuous flow of nutrient film in a shallow trough". In a dedicated grow tray, only an extremely thin layer of nutrient solution flows along the bottom of the trough. Crop roots are partially submerged in the film and partially exposed to air—this not only ensures roots efficiently absorb water and nutrients but also guarantees sufficient oxygen supply through air contact, avoiding root hypoxia and rot common in traditional hydroponics.

The stable operation of the NFT system relies on the collaboration of multiple components. This advanced hydro farming equipment integrates all key parts to optimize crop growth and nutrient delivery. The key components and their functions specified are as follows:

1. Grow Tray: Serves as the carrier for nutrient solution flow and crop planting, available in three types—Flat (HN1), A-Frame (HN2), and Vertical (HN3). All adopt a shallow trough design to form a thin nutrient film, with structural differences only to adapt to space needs.

2. Mixing Tank: Stores and prepares crop-specific nutrient solutions, ensuring the nutrient solution concentration and pH value meet crop requirements.

3. Water Pump: The core power source, which delivers the nutrient solution from the mixing tank to the grow tray through the filling pipe, providing power for circulation.