| Specification description | Quantity | Unit |

| Box body main structure |

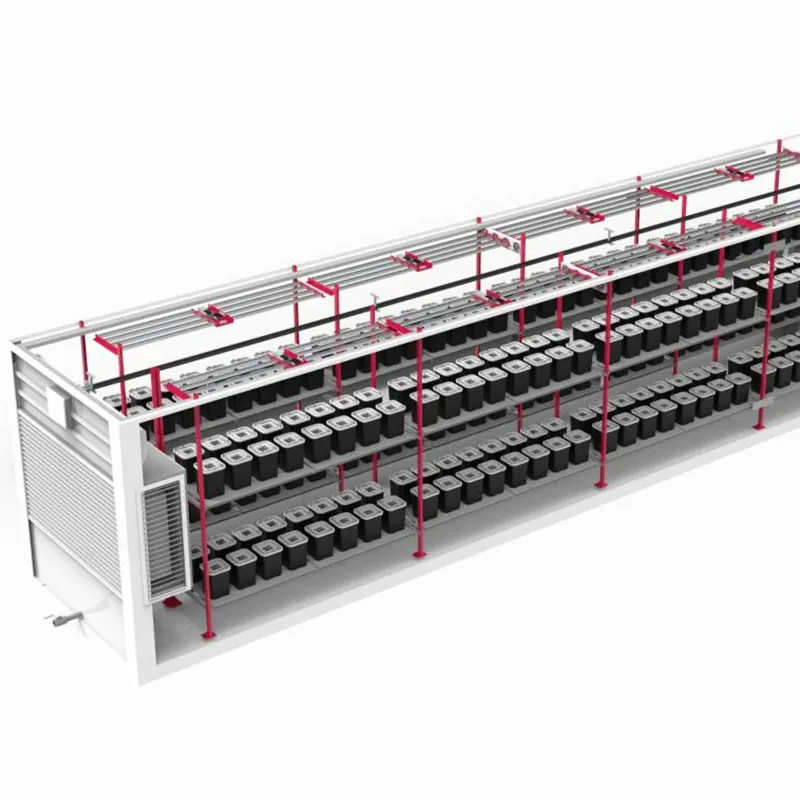

| Main structure | Standard 40-foot refrigerated container (high-density polyammonia ester insulation layer, with remarkable thermal insulation effect, reducing later operational energy consumption) | 1 | item |

| Internal supporting facilities | T-shaped aluminum base plate (enhances the structural stability , can be used as a ground water recycling system) | 1 | item |

| Aluminum-zinc coated plate + laboratory-specific anti-slip floor mat |

| Double-layer clean panel partition + steel clean door |

| Internal decoration + hanging cabinet + cleaning cabinet + single-sided logo on the cabinet surface |

| implant system |

| Planting module | 1.Number of planting layers: 5 tiers(Single-layer planting height: 360 mm)

2.Frame material: Powder-coated steel frame

3.Dimensions of a single unit: 97,000 mm × 740 mm × 2,500 mm (L × W × H)

4.Vertical rack cultivation system; operational aisles allow for normal activities such as planting, harvesting, and adding nutrient solution without obstruction

5.Layer spacing is designed to accommodate the growth and harvesting needs of various leafy vegetables, including lettuce, coriander (cilantro), and celery | 2 | group |

| Planting tray | 1.The cultivation planting boards and troughs are made of opaque ABS material, which complies with environmental protection standards. They are corrosion-resistant, durable, and not prone to wear. All moving or replaceable components have a service life of no less than 3 years under normal operating conditions.

2.The cultivation water trough adopts the NFT (Nutrient Film Technique) shallow-flow hydroponic cultivation mode, meeting the growth requirements of various vegetable varieties at different growth stages. A nutrient solution storage tank is placed at the bottom. The planting boards are easy to clean and disinfect. With a standard planting density, a single tray can hold 97 plants, and a total of 5,800 plants can be planted across 5 tiers. | 60 | set |

| Fill light | Full-spectrum LED plant-specific supplemental lighting | 60 | group |

| Fertilization system | 1) Kamoer 3-channel peristaltic pump (speed adjustable) 2) Special aluminum alloy mounting bracket | 2 | set |

| Mother liquor tank | Blue fertilizer mixing bucket 10L | 6 | piece |

| Water filter |

| 1 | piece |

| Water storage tank | 1)Material: PP (Polypropylene)

2)Structure: Inlet and outlet ports, drainage pipe, etc.

3)Dimensions: 900 × 600 × 800 mm (L × W × H) | 1 | set |

| Nutrient solution storage tank | 1)Material: PP (Polypropylene)

2)Structure: Inlet and outlet ports, drainage pipe, oxygenation piping, access hatch, etc.

3)Dimensions: 8,200 × 620 × 220 mm (L × W × H) | 2 | set |

| Circulatory system | Circulation pump + circulation pipeline + supporting facilities | 2 | set |

| Seedling box | Three-layer seedling box + seedling tray + supplementary lighting + water supply and return pipelines, etc. | 1 | set |

| Lighting fixture | LED waterproof lighting fixture | 4 | set |

| Auxiliary materials | Lines, pipes, and installation accessories | 1 | item |

| Monitoring system |

| Temperature and Humidity Sensor | [Product Brand] TECLION

[Product Model] TKLN-WS-G/5

[DC power supply] 10-30VDC

[Temperature measurement range] -40℃-80°C

[Humidity measurement range] 0-100%RH

[Long-term temperature stability] ≤0.1°C/year

[Long-term humidity stability] ≤0.1%RH/year

[Temperature resolution] 0.1°C

[Humidity resolution] 0.1%RH

[Output signal] RS485(Modbus Agreement)

[Temperature accuracy] ±0.5°C(25°C)

[Humidity Accuracy] +3%RH(5-95%RH,25°C) | 1 | set |

| Carbon dioxide sensor | [DC power supply] 9-30V DC

[Measurement accuracy] ±1.5%FS

[Output signal] RS485 ( Modbus Agreement) | 1 | set |

| Water quality pH senso | [Measuring range] 0-14ph

[Resolution] 0.01ph

[Work pressure] 0-4bar

[Protection Level] IP68

[Output signal] RS485(Modbus Agreemwnt) | 2 | set |

| Water conductivity sensor | [Measurement range] 0-20000μs/cm

[Resolution] 0.01μs/cm

[Measurement accuracy] ≤±3%

[Work pressure] 0-4bar

[Protection Level] IP68

[Output signal] RS485(Modbus Agreement) | 2 | set |

| Liquid level sensor |

| 2 | set |

| Control system |

| Smart Management Control Platform | Control management system software, 1 set

1) Achieves management and detection display of various sensors such as temperature, humidity, CO2, etc. inside the plant factory.

2) Enables intelligent management of equipment including plant growth lights, humidification, fresh air systems, and constant temperature control. | 1 | set |

| Control cabinet | 1) High-definition 10-inch Siemens brand LED screen + Siemens PLC main unit + remote control module + electronic components + cabinet body | 1 | set |

| Environmental control equipment |

| Constant temperature unit | Central air conditioning heating and cooling unit (includes 485 communication module) | 1 | set |

| Fresh air system | Total heat recovery fresh air unit + supply & return air ducts + supply & return air vents | 1 | set |

| Interlayer ventilation | Interlayer breeze system | 30 | set |

| Dehumidifier | 90L/D | 1 | set |

| Oxygenation pump | Oxygen pump + aeration disc, etc. | 1 | set |

| carbon dioxide | 15L carbon dioxide steel cylinder + electromagnetic pressure reducing valve + supporting facilities | 1 | set |