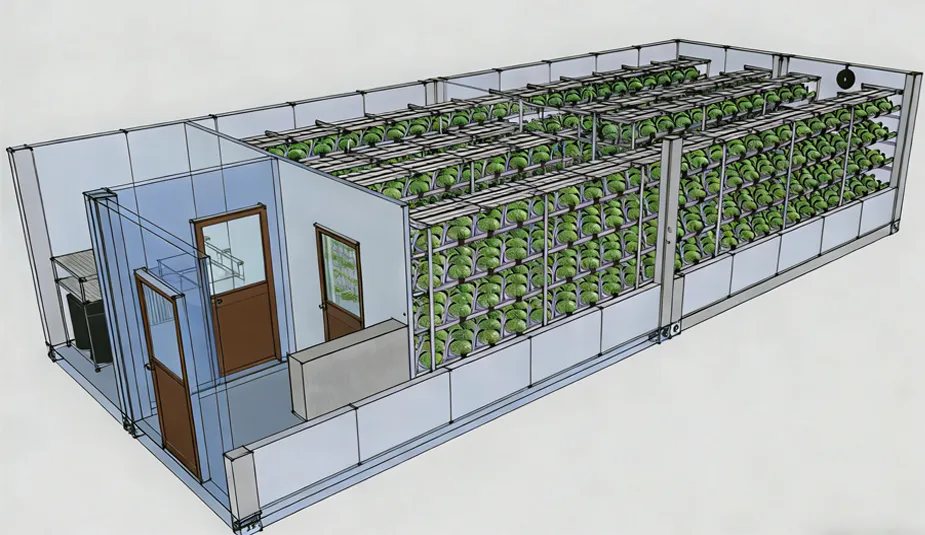

The container plant factory enables simultaneous cultivation of diverse vegetables and specialty crops on a single unit. Its core design significantly reduces external interference, meeting flexible and diversified planting requirements.

The container plant factory enables simultaneous cultivation of diverse vegetables and specialty crops on a single unit. Its core design significantly reduces external interference, meeting flexible and diversified planting requirements.

Grown in a closed, pollution-free, and controlled environment, the harvested products are rich in vitamins and 100% free of pesticide residues — meeting the highest food safety standards.

Achieve year-round continuous daily harvesting: With precisely controlled fertilizers and growing conditions, the crop growth cycle is significantly shortened compared to traditional farming, enabling fresh produce to be harvested daily.

Daily output efficiency is impressive: an average of 300-400 grams of fresh leafy vegetables per day—sufficient for personal consumption and small-scale commercial supply.

Leveraging the core advantages of containerized plant factories, the system features simple operation and durability, eliminating the need for heavy manual labor. Cleaning can be performed without disassembly, significantly reducing maintenance time.

The entire planting process can be controlled via mobile phone, featuring simple operation, durability, and no need for substantial manpower — enabling production management to be fully at your fingertips.

Transforming limited area into efficient planting environment can reduce land occupation and realize stable and expandable agricultural production.

By utilizing controlled artificial climate environments, crop cultivation can be conducted even during seasons traditionally challenging for farming, thereby avoiding seasonal supply shortages and securing more favorable market prices.

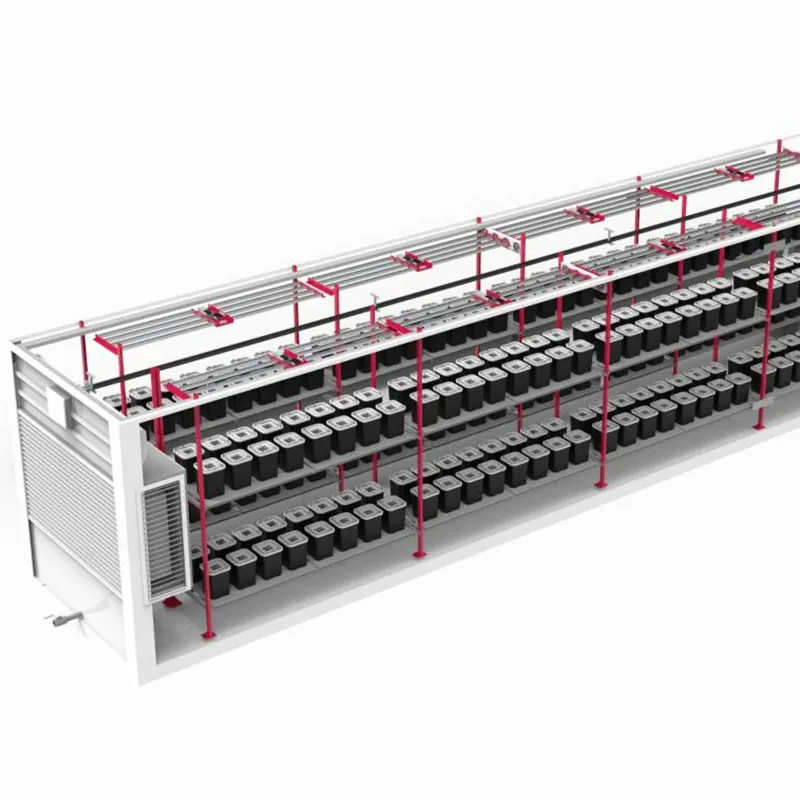

The Space Layout of Hydroponic Shipping Container System is a highly integrated, efficient design tailored for closed-loop agricultural production, consisting of three core functional zones: Cultivation Area, Power Area, and Operating Space.

As the core production zone, the Cultivation Area adopts multi-layer three-dimensional planting equipment, realizing large-scale, intensive, and digitized production. It uses professional environmental control materials (e.g., RADIXX insulation board) to maintain a clean, pesticide-free growing environment, maximizing yield per unit area.

The Power Area houses intelligent environmental control systems (temperature/humidity regulators, CO₂ controllers, etc.), which automatically adjust climate parameters (temperature, humidity, light) in real time—ensuring stable growing conditions without constant manual monitoring.

The Operating Space is equipped with an environmental control panel and operating stations, enabling simple, efficient management of the entire system (from equipment operation to harvest handling).

This rational layout optimizes space utilization, balances functional division, and supports the container’s all-weather, high-efficiency hydroponic production.

Compared to traditional agriculture, the hydroponic container system demonstrates significant economic advantages supported by data. Unlike the seasonal planting of conventional farmland, this system enables year-round cultivation, increasing annual yield by 2-3 times and eliminating income gaps during off-seasons. Its vertically integrated layout boosts yield per unit area by 30%, maximizing the utilization of limited space. With 90% of nutrient solution being recyclable, it reduces water and fertilizer costs by 60%. The enclosed environment also minimizes pest and disease risks, cutting pesticide expenses. Stable production avoids seasonal price fluctuations, ensuring consistent returns, while shorter growth cycles accelerate investment recovery, making it a more cost-effective agricultural model.

A hydroponic module system is a customizable setup designed for growing plants without soil, using water-based nutrient solutions. Different modules (e.g., seedling, leafy greens, strawberry, fruiting, and climbing) cater to specific crop needs.

Yes, but ensure compatible nutrient levels and water flow rates.

Example: Combine NFT for lettuce and DWC for basil in separate channels.

Reusable Media (clay pebbles, rock wool): Clean every 1–2 cycles.

Disposable Media (coco coir, peat): Replace after each harvest.

Climbing Modules save space with vertical growth and include adjustable supports (nets, poles) for vines like beans or melons.